Remote monitoring of tank levels is an important application of the Industrial Internet of Things (IIoT) in the oil, gas and chemical industries. It reduces logistics costs by digitalising and automating processes. Sensile Technologies conducted a study with one of its customers to achieve a better understanding of the gains made and to identify scenarios for achievable gains.

Savings of up to 30%

Telemetry equipment is widely recognised as helping to reduce logistics costs when integrated into an industrial IoT solution with high-performance algorithms. Our experience over more than 20 years with customers in the oil, gas and chemical industries shows that our telemetry solutions can reduce distribution costs by up to 30%.

Remote measurement and the analyses produced by our algorithms in the Oil Link™ portal make it possible to predict consumption, take action before stock runs out, calculate the ideal delivery date and plan deliveries automatically. In this way, our customers reduce their transport costs and optimise the volume delivered per kilometre travelled. Logistics costs are reduced as a result, as are CO2 emissions caused by distribution activities.

A before-and-after study to understand the impact of telemetry

In collaboration with one of our customers, a hydrocarbon distributor, we carried out a study to determine the financial benefit obtained through logistical gains, compared with the operational costs of the remote measurement system.

At the time of the study, the distributor had installed our telemetry units on 1% of its fleet of 166,000 tanks. It wanted to estimate the additional savings it could achieve by equipping a larger proportion of its fleet with our telemetry units.

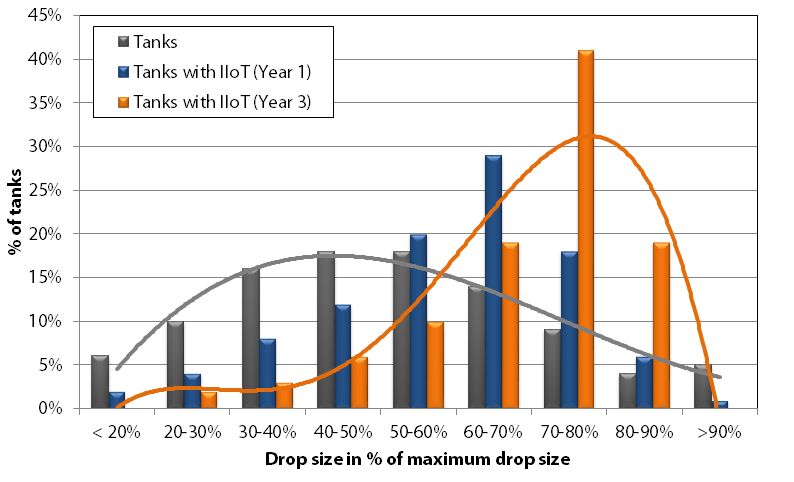

We began by analysing the 330,000 deliveries made in one year, before the distributor acquired telemetry units: the volume delivered then corresponded on average to 46% of the deliverable volume. After the installation of the remote measurement system, the average delivery volume had already reached 55% of the deliverable volume in the first year, rising to 64% in the second year.

Fewer deliveries and higher volumes

This case study shows that the adoption of a telemetry system in a smart supply chain means that larger volumes of product can be delivered during each transport journey, without risk of stock-outs. This customer obtained a 25% reduction in the number of deliveries.

Based on the figures provided by this study, three scenarios were drawn up with the customer. Projections of potential savings if there was an increase in the number of reservoirs connected ranged from €0.9m to €1.4m per year.

Factual support for decision-making

Using data collected from its own tanks and made available in the Oil Link™ portal, scenarios were developed based on the actual logistics performance that the customer obtained through our solution. As a result, he has had the benefit of real decision-making support, taking into account the way in which he implemented our solution in his supply chain.

Please contact us if you would like to carry out such a study and find out about the full potential of our industrial IoT solution for the oil, gas and chemical industries. We’re here to help!

To find out more about the results, please read our white paper: Impact of remote measurement in reducing logistics costs (PDF)