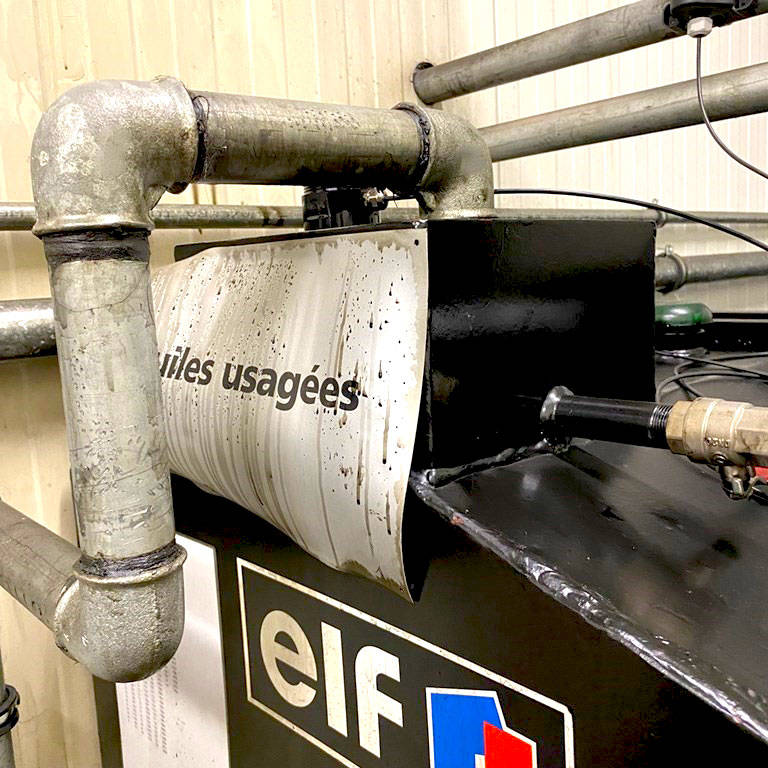

DISCOVER OUR IIOT SOLUTIONS FOR WASTE OIL TANKS ⸻

Autonomous, robust solutions for monitoring waste oil tanks.

Our solutions are designed to optimise the logistics of emptying used oil tanks.

Our Industrial IoT (Industrial Internet of Things) systems are installed very easily and operate reliably and accurately, regardless of location. Tank data and levels can be accessed via the Oil Link™ web portal.

BENEFITS

Up to 30% reduction in logistics costs

Route optimisation via our algorithm for predicting the ideal day for emptying tanks.

No more service interruptions or rush deliveries

Predictive analysis of tank levels and alarms triggered in the event of high levels.

Carbon footprint reduced

Optimisation of tank emptying means improved transport performance indicators.

Optimised planning and logistics

Remote monitoring of waste oil tank levels, detailed view of customer use, automatic planning of tank emptying.

Additional information monitored

Measurement of temperature and status of a burner or other relay.

How it works

With our IIoT solutions, you get a detailed view of tank levels, usage forecasts and automatic planning of deliveries and emptying.

01

The telemetry units are installed directly on the tanks, in less than 15 minutes flat.

02

They require no electrical connection and operate autonomously for 7 to 10 years.

03

Tank levels are measured and transmitted to the central server, which analyses the data.

04

Measured and forecast data can be consulted 24/7 via the Oil Link™ portal, with no need to install an app, even when you’re on the move.

05

Tank emptying is planned automatically using stock and forecast data exported via API to logistics planning software.

Our systems

Oil Link™ Cloud Portal

The interface between telemetry units and your logistics system

NETRIS®2

The telemetry unit with GSM transmission

NETRIS®3

The telemetry unit with LPWAN transmission

SENS.5 sensor

The pressure sensor for petroleum and chemical products

Ready to optimize your logistics or inventory with cutting-edge IIoT solutions?

Contact us today to receive expert advice tailored to your specific needs. Let’s work together to enhance your operational efficiency and ensure seamless monitoring. Reach out now and take the first step towards smarter tank management!